Vendor Managed Inventory Has The Following Benefits

- Vendor Managed Inventory Has The Following Benefits Tax

- Vendor Managed Inventory Has The Following Benefits Login

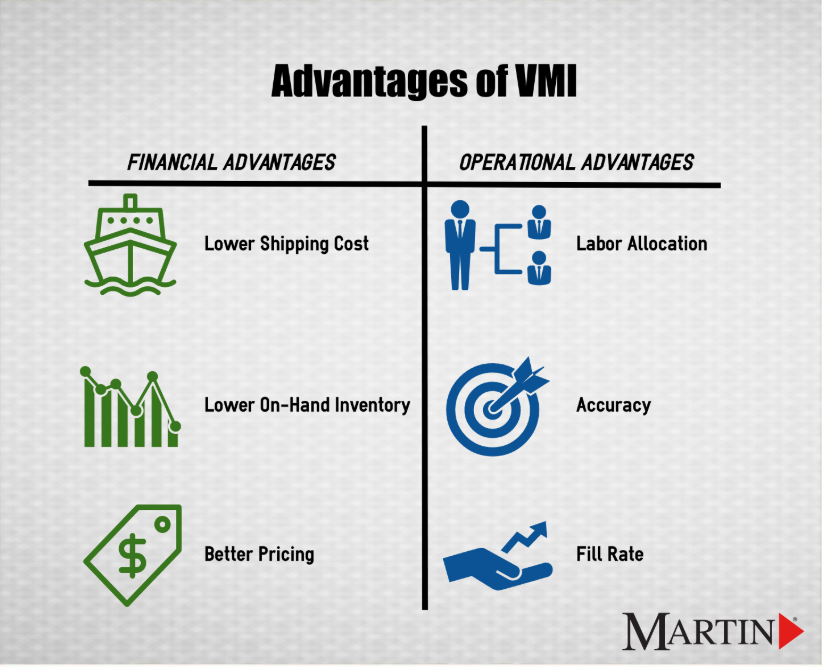

The vendor is usually the supplier, a manufacturer or a distributor. The benefits of the vendor-managed inventory process include: Enhanced visibility for vendor. Lower order volatility. Higher customer satisfaction. Reduced order lead times. Better transportation planning.

Vendor-Managed Inventory ( VMI) is a theory based inspired by integration in supply chain management regarding. In recent years, various partnerships like vendor managed inventory (VMI) approach have been used in inventory management as a means to cope with the.In the traditional inventory management, a retailer (sometimes called buyer) makes their own decisions regarding the order size while in VMI, a retailer shares their inventory data with a vendor (sometimes called supplier) such that the vendor is the decision-maker who determines the order size for both.

Thus, the vendor is responsible for the retailer's ordering cost, while the retailer has to pay for their own holding cost. This policy can prevent stocking undesired inventories and hence can lead to an overall cost reduction.

Vendor Managed Inventory Has The Following Benefits Tax

Moreover, the bullwhip effect is also reduced by employing the VMI approach in a buyer–supplier cooperation. As replenishment frequencies play an important role in integrated inventory models to reduce the total cost of supply chains which many studies fail to model it in mathematical problems. VMI is a family of business models in which the buyer of a product provides certain information to a supplier (vendor) of that product and the supplier takes full responsibility for maintaining an agreed of the material, usually at the buyer's consumption location (usually a store).A third-party logistics provider can also be involved to make sure that the buyer has the required level of inventory by adjusting the demand and supply gaps.As a symbiotic relationship, VMI makes it less likely that a business will unintentionally become out of stock of a good and reduces in the supply chain. Furthermore, vendor (supplier) representatives in a store benefit the vendor by ensuring the product is properly displayed and store staff are familiar with the features of the product line, all these while helping to clean and organize their product lines for the store. VMI can also decrease the magnitude of the.One of the keys to making VMI work is shared risk.

In some cases, if the inventory does not sell, the vendor (supplier) will repurchase the product from the buyer (retailer). In other cases, the product may be in the possession of the retailer but is not owned by the retailer until the sale takes place, meaning that the retailer simply houses (and assists with the sale of) the product in exchange for a predetermined commission or profit (sometimes referred to as consignment stock). A special form of this commission business is, where VMI is usually applied but its use is not mandatory.This is one of the successful business models used by and many other. Oil companies often use technology to manage the gasoline inventories at the service stations that they supply (see ). Uses the technique with larger suppliers of manufactured goods. Contents.Classes in Vendor-Managed Inventory 1- Bi-Level VMI Mathematical ModelsThe first class of VMI, bi-level VMI mathematical model, includes two levels (or echelons) in a supply chain: vendor and retailer.

There are three types of VMI mathematical models developed from this class, which are single-vendor single-retailer VMI model, single-vendor multi-retailer VMI model, and multi-vendor multi-retailer VMI model. This class has been significantly developing. For example, single-vendor single-retailer VMI model was extended for multi-product case, the consignment stock (CS), and discount.2- Multi-Level VMI Mathematical ModelsThe second class is multi-level VMI mathematical model such as a single manufacturer-single vendor multi-retailer (SM-SV-MR) VMI model. Those studies fail to model replenishment frequencies cannot classified here.

As replenishment frequencies play an important role in integrated inventory models to reduce the total cost of supply chains which many studies fail to model it in mathematical problems.See also.References. Sadeghi, Javad (2015-02-22).

'A multi-item integrated inventory model with different replenishment frequencies of retailers in a two-echelon supply chain management: a tuned-parameters hybrid meta-heuristic'. 52 (4): 631–649. Sadeghi, Javad; Mousavi, Seyed Mohsen; Niaki, Seyed Taghi Akhavan (2016-08-01). 'Optimizing an inventory model with fuzzy demand, backordering, and discount using a hybrid imperialist competitive algorithm'. Applied Mathematical Modelling.

Vendor Managed Inventory Has The Following Benefits Login

40 (15–16): 7318–7335. Sadeghi, Javad; Mousavi, Seyed Mohsen; Niaki, Seyed Taghi Akhavan; Sadeghi, Saeid (2014-10-01).

'Optimizing a bi-objective inventory model of a three-echelon supply chain using a tuned hybrid bat algorithm'. Transportation Research Part E: Logistics and Transportation Review. 70: 274–292. ', Datalliance, Retrieved Aug.

16, 2016. ', NC State University Suppy Chain Resource Cooperative, Retrieved Aug. Accessed 9 June 2014.

', CGR Products, Retrieved Aug. 16, 2016. Yao, Yuliang; Evers, Philip T.; Dresner, Martin E. Retrieved 2018-10-15. Sadeghi, Javad; Sadeghi, Saeid; Niaki, Seyed Taghi Akhavan (2014-07-10). 'Optimizing a hybrid vendor-managed inventory and transportation problem with fuzzy demand: An improved particle swarm optimization algorithm'.

Information Sciences. 272: 126–144. Sadeghi, Javad; Mousavi, Seyed Mohsen; Niaki, Seyed Taghi Akhavan; Sadeghi, Saeid (2013-09-01). 'Optimizing a multi-vendor multi-retailer vendor managed inventory problem: Two tuned meta-heuristic algorithms'. Knowledge-Based Systems. 50: 159–170. javad, sadeghi; ahmad, sadeghi; mohammad, Saidi mehrabad (2011-09-29).

Journal of Optimization in Industrial Engineering. 0 (9). Zavanella, Lucio; Zanoni, Simone (2009-03-01).

'A one-vendor multi-buyer integrated production-inventory model: The 'Consignment Stock' case'. International Journal of Production Economics. 118 (1): 225–232.

Sadeghi, Javad; Mousavi, Seyed Mohsen; Niaki, Seyed Taghi Akhavan (2016-08-01). 'Optimizing an inventory model with fuzzy demand, backordering, and discount using a hybrid imperialist competitive algorithm'. Applied Mathematical Modelling.

40 (15–16): 7318–7335. Sadeghi, Javad; Mousavi, Seyed Mohsen; Niaki, Seyed Taghi Akhavan; Sadeghi, Saeid (2014-10-01). 'Optimizing a bi-objective inventory model of a three-echelon supply chain using a tuned hybrid bat algorithm'. Transportation Research Part E: Logistics and Transportation Review. 70: 274–292.Literature. Tempelmeier, H. Inventory Management in Supply Networks—Problems, Models, Solutions, Norderstedt:Books on Demand.

Franke, P. Vendor-Managed Inventory for High Value Parts—Results from a survey among leading international manufacturing firms.External links. // Encyclopedia on Supply Chain Management, edited.